Category: Virgin

Vendor:Polymer in Stock

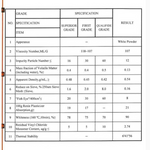

Polyvinyl Chloride Sg5

White and fluid, PVC Resin SG5 is a resin. To obtain a broad range of desired properties needed for numerous applications, the resin can be combined with a number of additives. PVC is a multipurpose material that is thermally, chemically and water resistant, as well as having exceptional color retention. A thermoplastic polymer with many applications, PVC Resin SG5 is well-known for its remarkable stiffness, longevity, and chemical resistance.

SG5 provides excellent performance in the production of pipes, profiles, bottles, and other products, with a broad range of applications ranging from construction to healthcare. Due to its superior cost-effectiveness and processability, it is a highly favored option across multiple global industries. PVC Resin SG5 reliably produces high-quality results in both consumer goods and building materials, guaranteeing dependability and lifespan in every application.

Uses of PVC Resign Sg5

Building: Because of its strength, resistance to chemicals, and ease of processing, it is widely used in the building industry to manufacture pipes, fittings, window profiles, and siding.

Packaging: Because of its superior clarity, toughness, and barrier qualities, it is used in packaging materials such bottles, containers, and films.

Automotive: Because of its strength, heat resistance, and affordability, it is used in upholstery, under-the-hood components, and interior parts for automobiles.

Healthcare: Because of its biocompatibility, elasticity, and resistance to sterilization processes, it is used in medical tubing, blood bags, and IV containers.

Electrical: Because of its superior electrical qualities and flame retardancy, it is used in cables, conductors, and insulation materials.

Consumer Goods: Because of its adaptability, low cost, and safety, it is utilized in the production of numerous consumer goods, including household goods, toys, and shoes.

Industrial Applications: Because of its toughness and chemical resistance, it is used in a variety of industrial applications to fabricate conveyor belts, industrial curtains, and protective garments.

RECENTLY VIEWED PRODUCTS

+971 509205838

+971 509205838