Category: Recycled Material

Vendor:Polymer in Stock

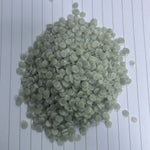

Our rHDPE Granules is recycled using high quality feedstock by a reliable supplier, ensuring that you receive a premium material product for your manufacturing needs. This (regrind or polymer) material is perfect for a variety of applications, including the production of new plastic products and other industrial uses. Please contact us for any technical guidance related to the material.

-

Material Type: High-Density Polyethylene (HDPE) – Recycled Granules

-

Quantity: 200 MT

-

MFI (Melt Flow Index): : 0.7 g/10 min

-

Port of Loading: UAE

-

Color: Grey and Black

-

Packaging: Jumbo bags

MOQ (Minimum Order Quantity): 25 MT -

Stock Availability: In stock, in production

-

Country of Origin: UAE

-

Volume: Available consistent

-

Container Loading: 20 and 40 Feet

-

Can Export To: All part of the World

-

Usage: Blown Film Production – Used in packaging films, industrial liners, and heavy-duty films.

Tarpaulin Manufacturing – Ideal for making waterproof tarpaulins, covers, and protective sheets.

Agricultural Films – Suitable for mulch films, greenhouse covers, and pond liners.

Industrial & Construction Use – Durable for weather-resistant and moisture-proof applications.

HDPE Film Grade Recycled Granules (MFI 0.7) – For Blown Film & Tarpaulin

Our HDPE Film Grade Recycled Granules are a high-quality, eco-friendly solution designed for blown film extrusion and tarpaulin manufacturing. With a Melt Flow Index (MFI) of 0.7, this material offers excellent strength, durability, and flexibility, making it ideal for heavy-duty film applications.

Key Features:

Sustainable & Eco-Friendly – Made from high-quality recycled HDPE, reducing environmental impact.

Superior Strength & Durability – High tensile strength and tear resistance, perfect for tough applications.

Excellent Processability – Ensures smooth extrusion with stable film formation.

Good Weather & UV Resistance – Ideal for outdoor applications like tarpaulins.

Strong Moisture & Chemical Resistance – Ensures protection in industrial and packaging applications.

Technical Specifications:

-

Material Type: High-Density Polyethylene (HDPE) – Recycled Granules

-

Melt Flow Index (MFI): 0.7 g/10 min (190°C / 2.16 kg)

-

Density: ~0.940 - 0.955 g/cm³

-

Processing Method: Blown Film Extrusion

Applications:

Blown Film Production – Used in packaging films, industrial liners, and heavy-duty films.

Tarpaulin Manufacturing – Ideal for making waterproof tarpaulins, covers, and protective sheets.

Agricultural Films – Suitable for mulch films, greenhouse covers, and pond liners.

Industrial & Construction Use – Durable for weather-resistant and moisture-proof applications.

Processing Guidelines:

-

Recommended extrusion temperature: 180°C - 220°C

-

Compatible with mono-layer & multi-layer film structures

-

Suitable for high-strength, heavy-duty film applications

Why Choose Our HDPE Recycled Granules?

Our high-purity recycled HDPE granules offer cost-effective, high-performance, and eco-friendly solutions for film manufacturers, ensuring durability and strength while supporting sustainability.

Bulk supply available for industrial use.

-

Contact for Orders

For pricing, stock inquiries, or detailed specifications, please contact: -

Email: annabelle@polymerinstock.com

-

Phone: +971 50 920 5838

Our Quality Assurance and Shipping Process

Material Guarantee:

We assure that the material meets the specifications as per loading pictures and samples provided prior to shipment. Customer satisfaction and transparency are our top priorities.

Step-by-Step Process:

1. Quality Inspection:

-

Quality Control (QC) team inspects the material before shipment.

-

Videos and images are captured and shared with the customer for approval.

2. Container Booking:

-

Container is booked on the next available vessel.

-

Shipping schedule and booking details are shared with the customer.

3. Loading & Documentation:

-

The material is carefully loaded and documented.

-

Loading process images and videos include:

-

Material condition

-

Loading procedure

-

Container and seal numbers

-

Draft Bill of Lading (BL) is shared for verification.

4. BL Draft Confirmation:

-

The customer reviews and confirms the BL draft.

-

The Original Bill of Lading (OBL) is issued.

-

A copy of the OBL is shared with the customer.

RECENTLY VIEWED PRODUCTS

+971 509205838

+971 509205838