Category: Virgin

Vendor:Polymer in Stock

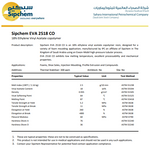

EVA VIRGIN SIPCHEM 2518

The EVA VIRGIN SIPCHEM 2518 product line is the pinnacle of ethylene vinyl acetate (EVA) perfection. It is well-known for its superior quality and adaptability, making it perfect for a wide range of uses. Outstanding performance and durability are guaranteed by its outstanding qualities, which can be applied to films, foam goods, packaging, or footwear.

Expect exceptional flexibility, robustness, and chemical resistance from EVA VIRGIN SIPCHEM 2518, which makes it a top option for many sectors. Its dependability is unmatched and may be used for anything from improving product packaging to offering comfort in shoes. With EVA VIRGIN SIPCHEM 2518, you can elevate your projects and enjoy unmatched quality and creativity in each application.

Uses of EVA VIRGIN SIPCHEM 2518

Packaging: Because of its superior clarity, flexibility, and heat-sealing qualities, EVA VIRGIN SIPCHEM 2518 is used in the packaging industry to manufacture flexible packaging films, pouches, and bags.

Footwear: Because it is lightweight, shock-absorbing, and cushioning, it is frequently used in the footwear industry to make midsoles, insoles, and shoe soles that give the wearer comfort and support.

Foam Products: Because of its softness, resilience, and durability, EVA VIRGIN SIPCHEM 2518 is used in the manufacturing of foam products like yoga mats, workout mats, and cushioning materials.

Automotive: It is utilized to make interior elements that are both aesthetically pleasing and comfortable, like headliners, armrests, and door panels.

Medical: Because of its biocompatibility and shock-absorbing qualities, EVA VIRGIN SIPCHEM 2518 is also utilized in the medical industry to make cushioning materials, prosthetic limbs, and orthopedic braces.

Stationery: Because it is so simple to cut, shape, and glue, it is used in the stationery business to create foam sheets, craft materials, and adhesive-backed goods.

Construction: Because of its thermal insulation qualities and moisture resistance, EVA VIRGIN SIPCHEM 2518 is used in the construction industry to manufacture soundproofing materials, insulation sheets, and sealing tapes.

RECENTLY VIEWED PRODUCTS

+971 509205838

+971 509205838